QUALITY PLANNED AND APPROVED!

Quality Planning

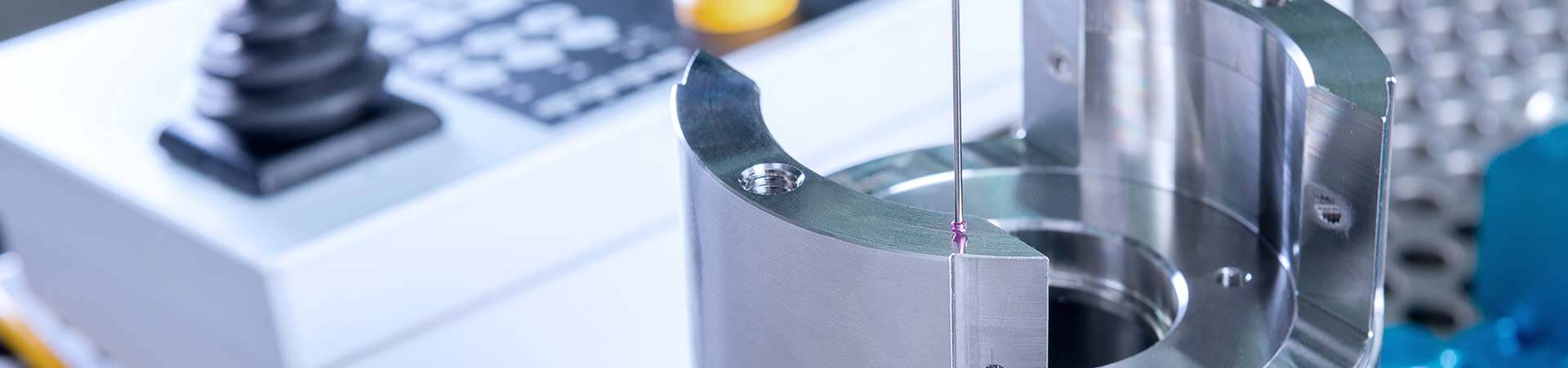

Quality inspections are an integral part of our production process. Your product specification and our process expertise built the foundation of our quality inspection process. Every part gets checked individually: Starting with the received raw materials to the inspection of the individual production steps up to delivery. At Kohler Präzisionstechnik: Quality is a planned process – instead of a simple test in the end!

All incoming materials are checked for faults.

The identification of rod material or saw sections is made manually with spectrometers. Incoming goods such as purchased parts and deliveries are checked by external productions partners to secure smooth processing.

During production, all relevant parameters are checked and directly documented in our CAQ system by our qualified staff.

All steps of our production process are carefully documented in our CAQ-system. On request, we will provide already documented measurement data or run 100% audits.

All manufactured goods are inspected and documented prior to shipment from our employees in the quality control department. Components with particularly high standards can undergo 100% tests.